Description

1. General requirements

1.1 The spraying of cleaning water and the dissolution and stripping of cleaning solution can assist in cleaning the inorganic residues (such as lead, mercury, cadmium, arsenic, etc.) and organic residues (such as industrial dyes, hormones, grease, dust, etc.) of laboratory glassware or plastics. After cleaning, the samples can be dried.

*1.2 The organic residue after cleaning is less than 0.1mg/L, and the metal ion residue is less than 0.02mg/L. The provincial authoritative experimental report or certification on the cleaning effect must be provided. In order to ensure the accuracy of the experimental results of trace analysis, the equipment has passed ISO9001, CE and other relevant international authoritative certifications.

1.3 The power supply voltage is 220V.

2. Structural design

2.1 Double-layer detachable heat insulation and sound insulation shell, the inner cavity is made of 316L stainless steel, and the outer shell is made of 304 stainless steel. The visible parts of the box and door should not have exposed screws and rivets to avoid rust in a humid environment.

* 2.2 The whole machine is of horizontal design. The height of the equipment is 1.1 meters, which is basically flush with the test bench, and the upper part is convenient for placing light weight items.

*2.3 There are two layers of cleaning racks in the cleaning cabin; the maximum cleaning height of the lower cleaning racks is 23cm, and the maximum cleaning height of the upper layer is 18cm.The maximum cleaning capacity is to clean 520 2ml liquid phase bottles or 120 vessels (volume flasks, conical flasks, etc.) with a diameter of 7 cm at a time.

*2.4 The original double-layer vacuum glass door is adopted, which can clearly see the internal cleaning, effectively heat insulation and reduce energy consumption.

2.5 It has two water inlets, which can be connected to tap water and pure water at the same time, and which water needs to be entered can be selected through the operation of the control panel.

3. Control system

*3.1 The industrial PLC microcomputer control system is adopted, without ordinary circuit board and single-chip microcomputer control. Industrial PLC is a professional microcomputer, which has special standards and designs for waterproof, anti-electricity, anti-magnetic, etc., and can directly upgrade the control software without changing the circuit, which is easy to upgrade.

*3.2 The control system adopts 7-inch color LCD touch screen, full Chinese operation interface, and Chinese prompts for operation and alarms.

*3.3 The control system has 12 standard cleaning procedures and 99 custom cleaning procedures, which can be set and adjusted for different utensils and requirements.

3.4 The control system adopts three-level password setting, which is convenient for management and operators of different levels to set and manage the parameters.

4. Cleaning system

*4.1 The cleaning water pump is a professional European original imported circulating pump. Its water output is 800L/min, the water output is large, and the scouring force is large. The circulating pump fan blades have been treated with high temperature resistance and can work normally under the disinfection water temperature (above 93 ℃).

*4.2 The washing cabin adopts two parallel water supply, and the side accepts water structure. The structure that the top part receives water and the central part all the way to supply water is not used.The two channels provide water at the same time, reducing the water pressure loss of the one channel of water supply, so that the upper and lower layers have the same water output; Receiving water on the side part, and there is no need to find a water receiving port. It is easy to operate, and the connector is not easy to damage.

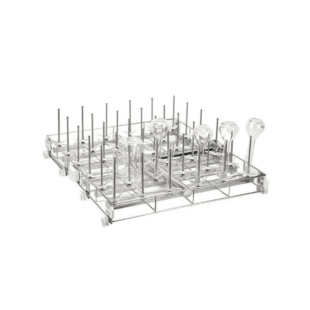

*4.3 Both cleaning racks adopt side water inlet and central water outlet structure. The water is discharged from the middle part, and the washing rack connects the water to the middle and distributes the water evenly to each spray column to ensure that each spray column discharges water evenly and the effect of cleaning utensils is consistent.

*4.4 The spray columns of the cleaning rack shall be distributed in parallel rather than around the center, so as to ensure the consistent distance between each spray column and facilitate the placement and estimation of utensils while increasing the cleaning amount.

*4.5 The cleaning rack does not have a tall central water inlet pipe, which saves space and is convenient to place; the upper and lower floors of the cleaning rack can be interchanged to facilitate the arrangement of utensils.

*4.6 The cleaning cabin has a built-in double-layer 360-degree rotating spray arm, and the nozzle adopts a fan-shaped nozzle design, which sprays a fan-shaped water curtain with large scouring force and no dead ends. No simple small hole nozzle is used to reduce the dead angle of external spraying.

4.7 The glassware washer adopts an automatic heating system during cleaning, and the heating temperature is adjustable. The maximum temperature can reach 93°C, reaching the disinfection level.

4.8 The cleaning solution and neutralization solution are automatically added by two peristaltic pumps, and the added dosage can be set.

5. Drying system

*5.1 Injection hot-air drying. The filtered air is heated and directly connected to the spray pipe. The air temperature can be adjusted from room temperature to 120°C. The hot air will not only dry the utensils but also dry the pipe at the same time to prevent internal water accumulation.

5.2 The dry air passes through a high-efficiency filter with an efficiency of 99.99% to ensure that the air entering the cleaning cabin is clean and avoiding secondary pollution of the cleaning items.

*5.3 With filter alarm function, it can automatically determine whether the filter needs to be replaced. No matter the filter expires or is accidentally damaged, an alarm will be issued and a Chinese prompt will be given.

5.4 Equipped with dual steam condensing devices to prevent the discharge of hot steam into the laboratory during work from polluting the experimental environment.

5.5 The internal and external balance air pressure hole design makes it unnecessary to circulate and supplement the internal humid air during drying, effectively shortening the drying time.

6. Safety protection

6.1 Safe door lock design, the door body is locked and cannot be opened during the cleaning process, preventing water spraying and scalding caused by misoperation;It has the function of the emergency door opening, which can quickly open the door and take out the utensils after power failure.

6.2 The door lock adopts the upper two-point locking structure. The left and right sides of the upper door body are connected to the door frame for locking. Compared with the single-point door lock connected in the middle, the seal is more reliable and prevents water and steam from overflowing.

6.3 It has a complete protection function, with a lack of cleaning agent alarm, the main washing pump over-temperature protection function, heating and anti-dry function, the main washing pump idling protection function, water level sensor detection function, cleaning chamber over-temperature protection function, all have Chinese prompt and alarm reminder.

6.4 It has the function of program self-checking and equipment self-cleaning, which can perform self-checking on the set program. After cleaning, the equipment can also be automatically cleaned to reduce residues.

Specifications

| Model | CA-LWD-200 |

| The volume of the cleaning chamber | ≥200L |

| Package Dimension (W*D*H)(mm) | 1110*940*1350 |

| Power supply (V/HZ) | 220V/50Hz |

| Water cleaning power | ≤0.75KW |

| water heating power | ≥5KW fast heating |

| drying power | ≥2.1KW |

| air volume | ≥120L/M3 |

| Water temperature control | room temperature to 99℃ |

| Configure 2 cleaning racks | |

| Equipped with imported one barrel of cleaning liquid and one barrel of neutralizing liquid. | |

Reviews

There are no reviews yet.